What Are The Major Types Of Taps And Their Features?

Taps are essential tools used to cut internal threads in holes to enable screws or bolts to secure parts together. These invaluable workshop devices have various designs, materials, cutting actions, and specifications for diverse threading applications and requirements, from hand taps to machine taps. This article covers common types and features of taps.

Before you look at different designs of taps, you will need to learn about the different types of taps available. In the next section, you will learn about the various types of taps, along with their features. Furthermore, this article will also share details about what you need to consider before buying taps. Hence, to learn more, read on through to the end of the article.

Types Of Taps And Their Features

If you are out in the market to buy taps, it can be overwhelming for you to look at the different options in front of you. However, once you learn the different types of taps and their features, you will be in a better position. The following are some of the major types of taps, along with their features:

Straight Flute Taps

The most widely used and versatile tap variety is the straight flute tap. As their name suggests, straight flute taps have longitudinal flutes extending up their cutting section in straight lines. They feature 2, 4, or 6 flutes on the cutting cone area of the taper near the tip.

Straight flute taps can thread most typical materials, from ferrous metals to non-ferrous alloys like aluminum. Their simple but sturdy straight-fluted design makes these economical general-purpose tap types suitable for through and blind hole threading.

Pipe Taps

Pipe taps are designed to cut or repair threads on pipes, plumbing connections, and fittings. They cut specialty tapered threads optimized for creating strong, pressure-tight seals on cylindrical applications.

Pipe taps feature deeper, more sharply angled flutes between cutting ridges to facilitate chip evacuation when tapping internally in pipes or fittings. This helps prevent jamming inside confined tubular spaces. They also have longer taper leads, enabling gradual engagement into the thick pipe walls.

Screw Thread Insert Taps

Screw thread insert taps, similar to spiral flute taps, utilize helical-style flutes that spiral up around the tap’s body. The angled flutes act as miniature conveyors that continuously evacuate chips from the hole even when tapping blind, deep cavities. This gives screw thread insert taps superior performance in dead-end holes since chip accumulation cannot impede their progress.

Their unique design also enables faster cutting speeds over straight flute alternatives. However, they struggle with more brittle materials prone to crumbling versus curling chips.

Hand Taps

Hand taps provide portable, manual threading capabilities without needing powered machines. Sets frequently package together taper hand taps for starting holes, intermediate plug taps for threading middle regions, and bottoming taps for completing the ends of blind holes.

With attached T-handles, knurled round handles, or lever handles, hand taps facilitate controlled threading by bare hands but sacrifice speed. They mainly serve light-duty jobs and prototype development rather than high-volume production.

Tip Taps

The tip-tap represents a specialized variety engineered for precision accuracy in difficult-to-machine alloys. The tip taps clear chips through axial grooves extending from the notch forward along the body. The customized tip design makes accurate threading possible at low torque, even in temperamental substances like stainless steel.

Extrusion Taps

Extrusion taps contrast other varieties by displacing versus cutting threading stock. Instead of shearing swarf off the hole’s walls, these taps compact and cold form the material into the desired thread pattern. This action compresses the stock harder versus cutting it, increasing retained thread strength by up to 30% in ductile metals like copper, aluminum, and mild steel.

Extrusion taps thus produce superior threading integrity, resisting pull-out forces better after installation. However, they also require precise hole diameters and struggle in harder, non-malleable materials.

Materials Used In Taps

Taps consist of hardened steel cutting teeth integrated into various shank, flute, and body designs. However, manufacturers alter the steel’s composition to balance traits like hardness, durability, and productivity. Common tap materials include:

Carbon Steel

The most economical are carbon steel taps, which use simple steel alloys tempered for moderate strength and edge hardness. They suffice for general, low-abrasion threading tasks in typical structural metals. Carbon steel provides a cost-effective option when tapping volumes exceed tool lifespan between sharpening or replacements.

Cobalt Steel

Where extreme heat and friction arise from tapping hardened alloys, cobalt steel fends off intense forces. The addition of cobalt fortifies the molecular structure of the steel to withstand more heat and pressure without deforming. This makes cobalt steel taps the best choice for working with highly abrasive substances that cause rapid wear and tear through extreme friction.

Titanium Coatings

Another way tap makers boost longevity involves applying wear-resistant Titanium coatings. Diffusion of titanium atoms into the substrate steel’s surface enhances corrosion resistance. It also reduces tool friction, allowing faster speeds. Titanium nitride layers excel when processing highly abrasive metals where temperatures may diminish lubrication.

Factors To Consider Before Buying Taps

When you are trying to buy taps for your home or any other purpose, choosing the right fixtures is important. The following are some of the major factors you will need to consider before you buy the right taps for your home:

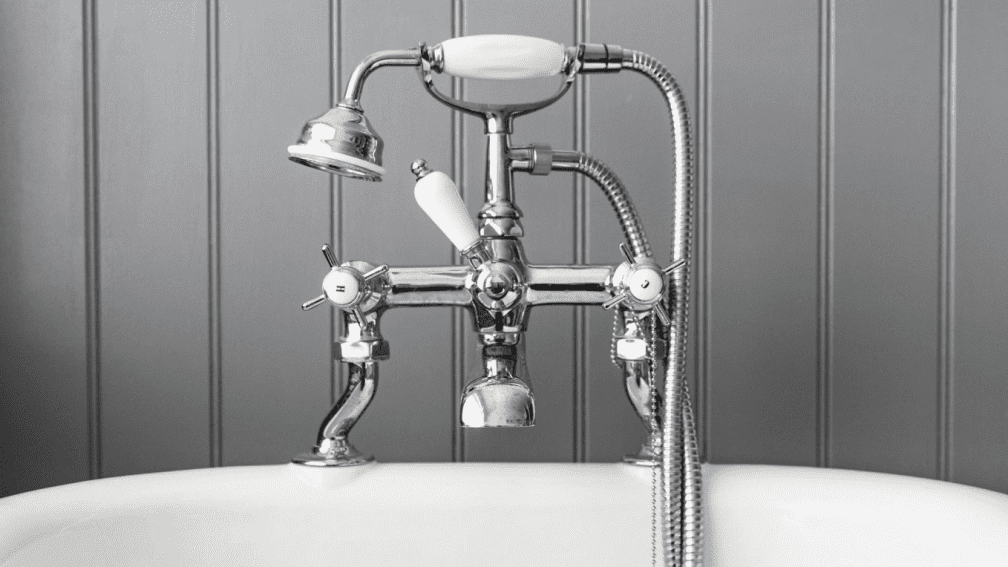

1. Design

The design is one of the most obvious aspects of a tap. You will need to buy a faucet or a tap that best suits your style. Furthermore, you will have to consider the position of the taps as well if you separate taps for hot and cold water. Additionally, there are different models for different needs. In addition, you must also consider the material of the tap that you are buying.

2. Price

Not every expensive item that you buy is better. Basically, you will need to buy those products that are cost-effective and of good quality at the same time. Contrarily, if something is affordable, it does not mean that it lacks the required quality.

3. Flow Of Water

When you are buying taps, you will also need to consider the flow of water through the tap. Here, you will need to buy based on your need. To find out the flow of water that you prefer, check your current taps in your home. Based on them, choose your needs and designs while you buy taps.

4. Durability

Although price, design, and features are important, they will not work in a tap of low quality. Hence, while buying taps, never compromise on the quality part. You will always need to make sure that the taps you buy are made of top-quality materials and have the capability to withstand erosion and corrosion over time.

5. Fitting Location

The design of the tap and the size that you buy will depend a lot on the position of the tap in your bathroom or your kitchen. Actually, there are different types of styles and fixtures available, and some of them offer different installation options. Hence, try to choose the one that best suits your needs.

Final Thoughts

Taps are used for the important function of cutting internal threads to enable fastened assemblies. When selecting a tap, consider the application’s materials, hole specifics, production volumes, and accuracy needs. Evaluating the various tap types and their respective features, cutting behavior, durability, and cost trade-offs will inform the best tap choice for optimal threading utility.

Continue Reading:

Leave A Reply