How To Upgrade Your CNC Machine With The Latest Accessories

As a professional, you understand the impact of technological advancement on your work. Upgrading your CNC machine with the latest accessories is not just about staying current but about pushing the boundaries of what’s possible, ensuring your work remains top-notch in a competitive industry.

We’re here to guide you through the process of upgrading your CNC machine.

Step 1: Assessing Your CNC Machine’s Capabilities

This is about understanding where your CNC machine stands today and where it can go tomorrow.

- Evaluating Existing Components: Begin by thoroughly inspecting your machine’s key components. Is your spindle delivering the desired speed and power? Does your motor provide the torque necessary for your projects? Is the controller smoothly interacting with your software? These answers will set the stage for your upgrade journey.

- Identifying Upgrade Needs: Reflect on the limitations you’ve encountered in your projects. Perhaps you’ve needed finer cuts or faster production times. This step is about aligning your machine’s capabilities with the demands of your projects, ensuring your upgrades are both meaningful and impactful.

Step 2: Understanding CNC Machine Accessories

Dive into the world of accessories, each designed to enhance your machine’s performance in unique ways.

- Types of Accessories: Learn about the wide array of accessories available. Tool holders, collets, work-holding devices, probes, and coolant systems each play a vital role in enhancing the precision and efficiency of your CNC operations. Take the time to research different manufacturers and what they have to offer, such as Summit parts and accessories.

- Accessory Compatibility: It’s crucial to match these accessories with your machine’s specifications. This ensures seamless integration and optimal performance. Again, it’s important to do thorough research. The last thing you want to do is waste time and money on parts that don’t work with your specific machine.

- Latest Innovations: Keep an eye on groundbreaking developments like wireless probes for enhanced measurement accuracy or high-speed spindles for quicker operations, ensuring your machine stays ahead of the curve.

Step 3: Crafting Your Upgrade Plan

Planning is the bridge between your current capabilities and your future aspirations.

- Setting Upgrade Goals: Define what success looks like for your upgrade. Is it about diversifying your production capabilities or ramping up production speed? Your goals should guide your upgrade decisions.

- Budget Considerations: Develop a budget that balances your aspirations with financial reality. Remember, the most expensive upgrades aren’t always the most impactful.

- Upgrade Timeline: Create a realistic timeline that minimizes downtime. This is about integrating new upgrades without halting your productivity.

Step 4: Selecting The Right Accessories

Now that you’ve researched the parts and accessories that are available, determined which works for your specifications, and have a budget in place, now is the time to narrow down your list. Choosing accessories is a strategic decision – it’s about finding the perfect match for your machine and your projects.

- Performance-Enhancing Accessories: Identify accessories that will directly boost your machine’s performance. Consider how high-speed spindles could refine your work or how automatic tool changers could streamline your processes.

- Cost-Effective Upgrades: Seek upgrades that offer significant benefits without a hefty price tag. Sometimes, a simple upgrade like a new cutting tool or a dust collection system can dramatically improve performance.

- User Reviews and Recommendations: Tap into the collective knowledge of the CNC community. User reviews and expert opinions can guide you toward the best choices for your specific needs.

Step 5: Implementing Upgrades with Precision

Okay, you have your new parts. Now it’s time to put them together. Installation is a critical phase, where attention to detail ensures the success of your upgrades.

- Installation Guide: Approach installation with care, adhering to safety protocols and manufacturer guidelines. This ensures not only a smooth integration but also the longevity of your machine.

- Troubleshooting Common Issues: Be prepared to address any challenges that arise during installation. Familiarize yourself with common issues and their solutions to ensure a smooth upgrade process.

- Maintenance of New Accessories: Regular maintenance extends the life of your accessories and ensures they continue to function at peak performance. This includes tasks like cleaning, lubricating, and inspecting for wear and tear.

Step 6: Mastering Advanced Techniques

Unlock the full potential of your upgrades with innovative techniques and practices.

- Maximizing Accessory Potential: Educate yourself on the full capabilities of your new accessories. Experiment with different settings and configurations to discover new ways to enhance your work.

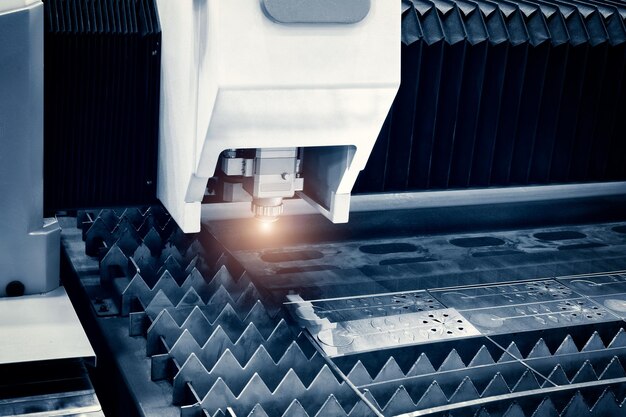

- Innovative Usage of Accessories: Think creatively about how you can use your accessories. For example, a rotary axis could open up new design possibilities, or a laser attachment might add a new dimension to your projects.

Step 7: Staying Ahead with Emerging Trends

Stay informed about the evolving landscape of CNC technology to maintain your competitive edge.

- Emerging Technologies: Anticipate how advancements like AI and 3D printing could transform CNC machining. Staying informed allows you to adapt and integrate these technologies as they become available.

- Predicting Accessory Evolution: Keep an eye on the future, anticipating how accessories might evolve. This forward-thinking approach ensures that your machine and skills remain relevant and in demand.

Conclusion: Your Path To CNC Mastery

Your journey towards upgrading your CNC machine is a testament to your commitment to excellence and innovation.

Each upgrade is a step towards enhancing your craftsmanship and efficiency. Embrace this journey as an opportunity to not just improve your machine, but to redefine the quality and scope of your work. Remember, in the world of CNC machining, staying ahead isn’t just about keeping pace—it’s about setting the pace.

Read Also:

Leave A Reply